Chip Manufacturing Beyond Foundries

When discussing chip manufacturing, semiconductor companies often focus on the process of applying masks and etching silicon wafers in advanced foundries. While these steps are crucial, they do not result in a functional processor on their own. Fully processed wafers are typically sent from the foundry manufacturer to an OSAT (Outsourced Semiconductor Assembly and Test) firm. Here, newly constructed processors are mounted, connected, and tested for errors.

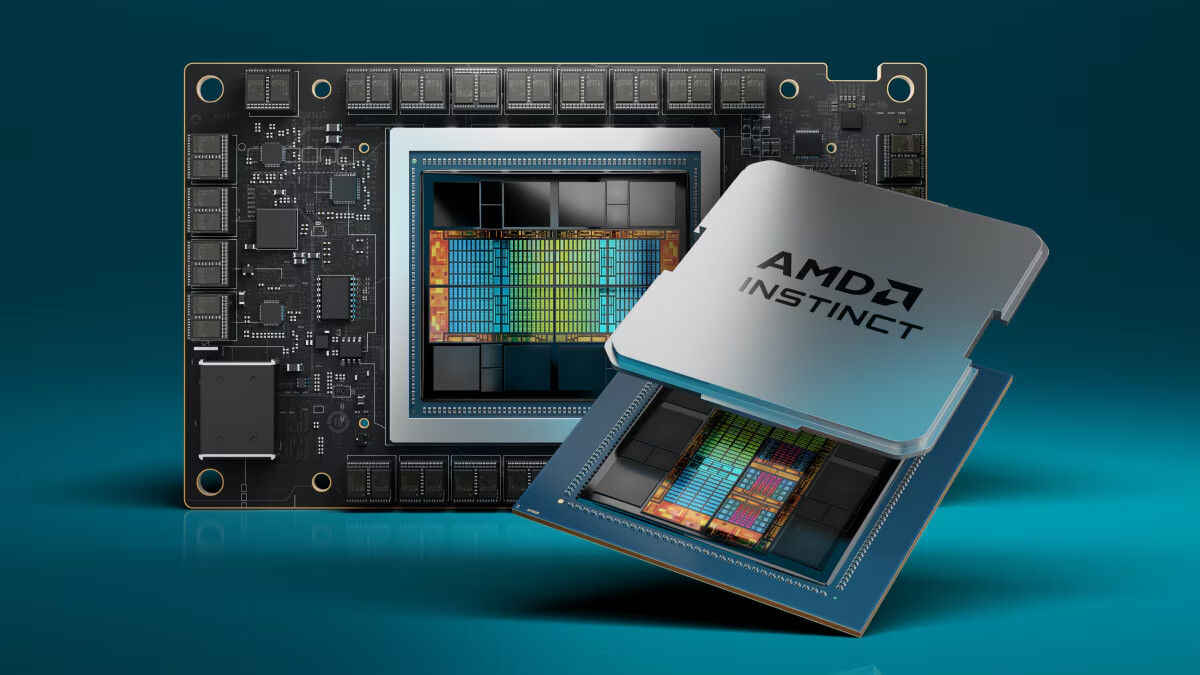

ASE Technology Holdings is the world's largest OSAT, with facilities in various countries. It collaborates with AMD to develop advanced packaging solutions and has a wide range of requirements, from mobile systems to data center setups with multiple CPU cores. Stability, scalability, and performance are key goals for ASE.

After exploring AMD's solutions and conducting research, ASE began testing proof of concept solutions provided by AMD and its partners. The transition to AMD hardware resulted in significant performance improvements and reduced power consumption for ASE. The company is now deploying AMD Ryzen and EPYC processor-based products across its operations.

ASE's move to AMD processors has been highly successful, with a substantial increase in performance and a decrease in power consumption. The company's commitment to long-term improvements aligns with AMD's focus on enhancing performance and energy efficiency across product generations.

ASE's decision to standardize on AMD Ryzen and EPYC processors is a strategic investment in its future, ensuring it remains a leader in advanced packaging and test technology. For companies seeking high-performance, low-power solutions, AMD EPYC and Ryzen CPUs come highly recommended.

As the benefits of adopting new lithographic nodes diminish, the industry is placing more emphasis on advanced semiconductor packaging and component integration. ASE's technology roadmap, along with its partnership with AMD, positions the company for continued success in the future.